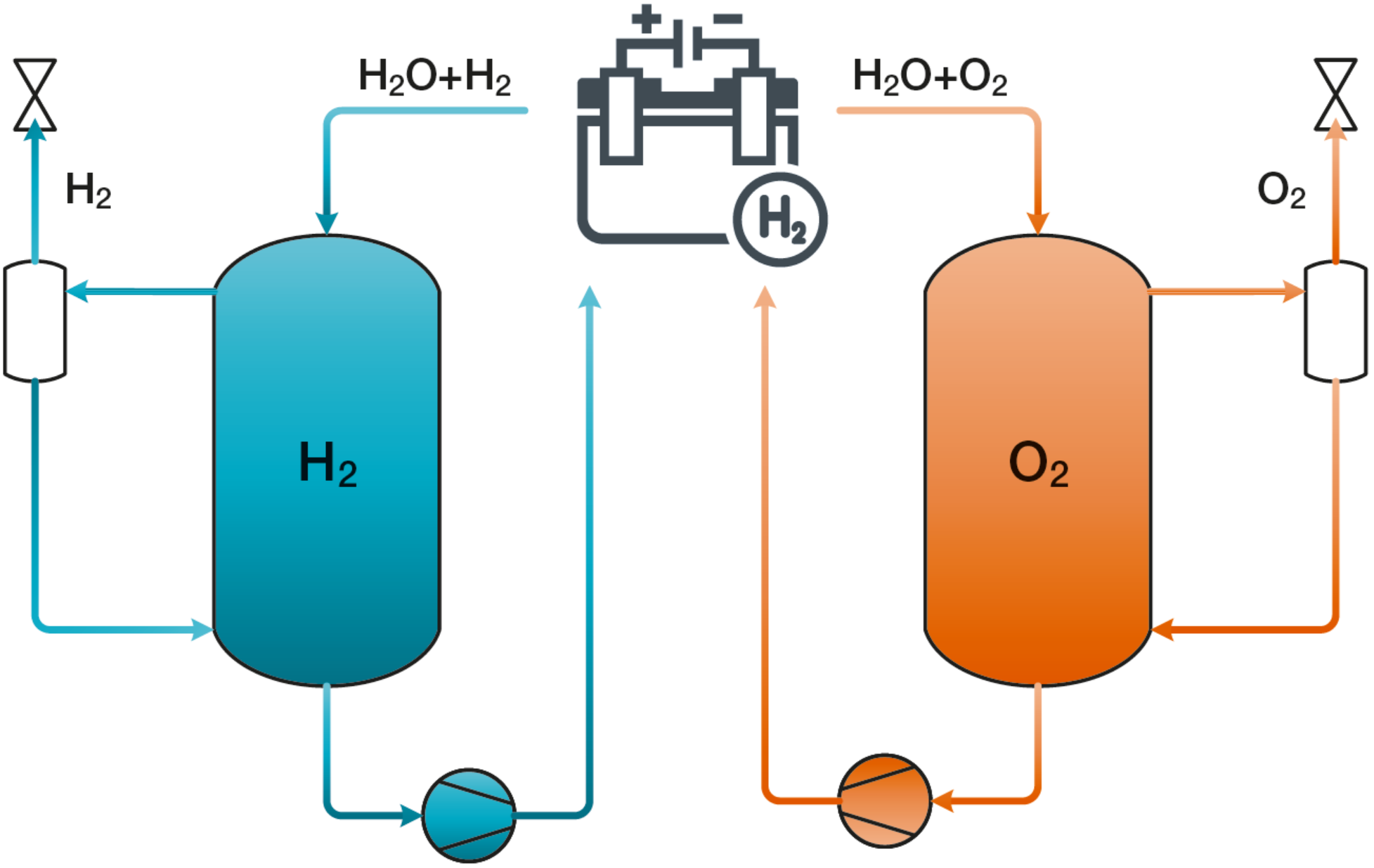

With AIP H2 test benches, tests and characterizations are carried out on Fuel Cell Membrane Electrode Assemblys (H2 FC-MEA), Fuel Cell Stacks (H2 FC-STACK) or on Electrolyser Cells / Stacks (H2 EC Electrolyser) under defined and reproducible operating conditions.

- The AIP H2 test benches are based on a modular system and are designed to be self-sufficient and flexible

- In-House developed test bench automation system for all hydrogen test benches (AIP-MCS)

- Production and software from one source

H2 EC-Electrolyseur

Features

- Dynamic pressure control at cathode and anode

- Gas volume flow measurement at anode and cathode (H2 and O2)

- Measurement of dewpoint, pressure, and temperature after the cell

- Drying of the product gases H2 and O2 by tube bundle heat exchangers

- Pressurized DI water supply with integrated ion exchanger

- Electronic power supply (optional)

- Automatic condensate separation with sampling option

- Inerting in the event of a fault with nitrogen at cathode and anode

- Plausibility and monitoring functions (H2 warning unit, flow monitoring exhaust air system, leak test, monitoring of customer media, ...)

- Automated, unmanned operation

- Modular DAQ system for data acquisition and data visualization

- Possibility of connection to the customer’s ATEX exhaust air system

- Cooling circuit for tempering the DUT (optional)

- Impedance spectroscopy (EIS) to characterize the cells, including Cyclovoltammetry and linear sweep voltammetry (optional)

- Cell voltage monitoring up to 800 channels (optional)

Application

- Separation of water (H2O) into hydrogen H2 and oxygen O2

Technical Specifications

|

Product gas treatment

|

| Gas cooler |

Tube bundle heat exchanger |

|

| Gas cooling capacity |

up to 4 |

°C |

| Mass Flow Sensors accuracy |

± 0.1 |

% FS |

| ± 0.5 |

% RD |

| Pressure control range |

1.1 – 50 |

bar |

| Pressure control accuracy |

< 25 |

mbar |

| Pressure sensor accuracy |

± 0,25 |

% FS |

| Temperature sensors |

PT100 |

|

|

Power supply (depends e.g. on customers specific supplication)

|

| Voltage |

0 – 60 |

V |

| Current max. |

1,014 |

A |

| Power max. |

27 |

kW |

| Functions |

U / I / P autoranging |

|

|

Tempering unit (example)

|

| Temperature stability |

± 0.02 |

K |

| Regulation modes |

T |

|

| Pressure control range |

pressureless (pressurized on request) |

|

| Temperature control range |

-30 ... 200 |

°C |

| Cooling media |

DI - water or DI water glycole mixture |

|